CLEAN COAL

SUSTAINABLE SOLUTIONS

Maximizing Use Of Low Sulfur Low BTU Coal

Retrofitting Coal Plants For Zero Emissions

Transforming Captured CO2 into Renewable Zero-Sulfur Diesel

Transforming Coal Waste Into Green Energy

THE GIFT OF FOSSIL FUELS

Continuing surprising scientific discoveries about our Earth reveal that the Sahara turns into a green Savanna every 20,000 years, including when atmospheric CO2 was possibly higher than today's levels, and Ice Ages occur every 100,000 years. Latest estimates for the Planet’s actual reserves of Oil, Gas, and Coal at current consumption rates are sufficient for THOUSANDS of years. New developments in production technology and exploration are adding to the abundance

AT SOME POINT IN THE DISTANT FUTURE, advanced technologies and a decline in usage by smart human activity could balance the Earth’s natural Fossil production to replenish resources. The most important issue TODAY is HOW we use these resources without harming the Environment

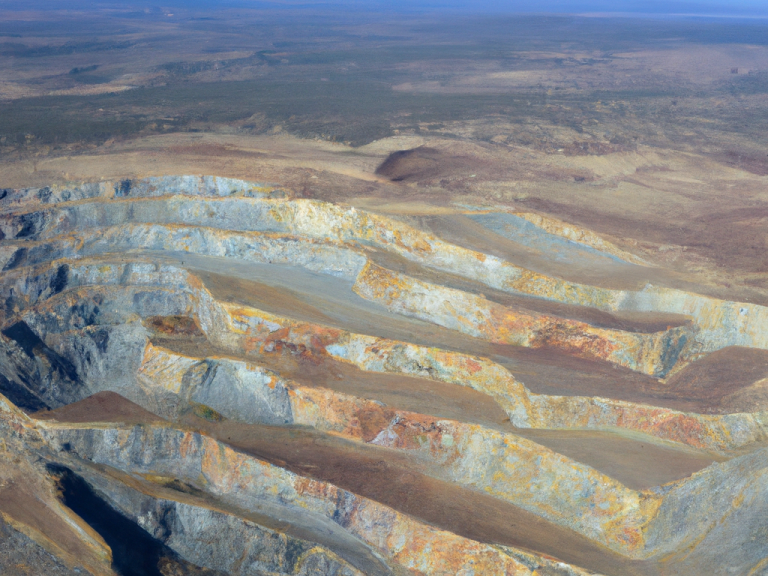

Mining Challenge –

TYPES OF COALS

Some Coal-producing regions have reserves with abundant Sulfur-rich, bituminous, easy to mine Coal. Sulfur adds to the calorific value, generating more electricity, but leads to greater SO2 emissions than Coal with a lower Sulfur content. Emission restrictions on this highly polluting type of Coal closed more than 546 Coal-fired power units, according to the US Energy Information Administration (EIA)

Many utilities have preferred low-Sulfur, cleaner burning Coal coming from other regions, even though the high-Sulfur Coal often is found in areas that are closer to where Coal-reliant power plants operate

IP Technology works well with BOTH - removes Sulfur, Chlorides, Ash, and other impurities for maximum clean performance, allows low BTU to be competitive with superior quality and higher BTU Coals

Maximizing Use Of Low Sulfur Low BTU COAL

SUSTAINABLE SOLUTION

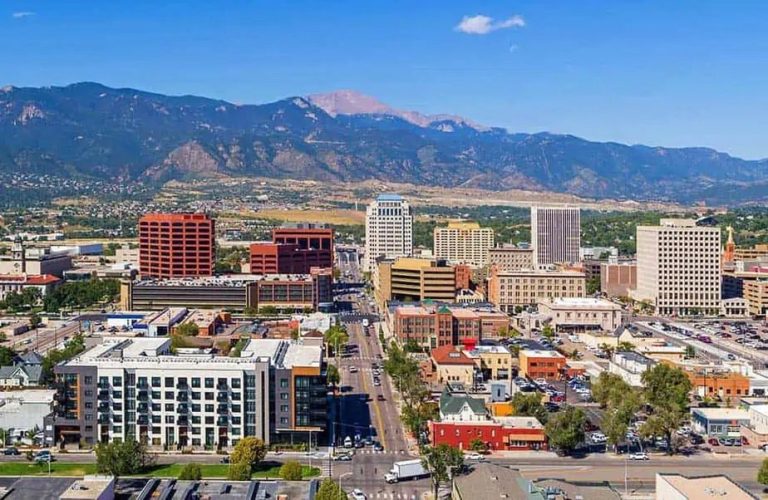

Retrofitting Coal Plants for ZERO EMISSIONS

SUSTAINABLE SOLUTION:

For existing Coal-fired Power Plants IP Technology will engineer facilities currently using Coal, and transform all Coal emissions, including CO2 and various tailings and residue, into Sulfur-free Renewable Diesel Fuel of the highest quality in a proprietary Zero-waste, Zero-emission, Zero-carbon footprint process

At the same time, the Plants will continue to produce electricity

If existing Coal-fired Power Plants are located near our Waste-to-Energy Plants which process Municipal, landfill, and other waste, including Coal and Coal waste, into Renewable Gas from this mixed feedstock, this Renewable Gas, consisting of 85+% Hydrogen, will generate more power for the Power Plant and is extremely cost-effective

Transforming Captured CO2 into Renewable Zero-Sulfur Diesel

Environmental challenge -

COAL PLANT EMISSIONS

Environmental challenge -

COAL WASTE

IP Technology transforms low-grade Coal and Coal Waste into fuels and electricity and can extract valuable metallurgical concentrates from Coal waste for commercial application

This Environmentally sound concept saves jobs and stimulates economic growth by providing inexpensive energy to households and industry instead of trying to produce “Renewables” that use up more energy than they deliver

Transforming Coal Waste into GREEN ENERGY

SUSTAINABLE SOLUTION:

REVIVING COAL’S POTENTIAL – CTL –

CLEAN COAL-TO-LIQUIDS TECHNOLOGY

Our IP Technology’s CTL process can refine low-grade Coal, various Coal wastes, old and new gob piles, and slurry ponds, into Zero Sulfur Renewable Diesel, Gasoline, and other fuels; Green Electricity, and ancillary products, such as materials for the production of quality cement, roofing, road construction, and others. With Zero-Emissions, zero Carbon footprint

CTL facilities can combine coal waste with such hydrocarbon feedstock as used tires, oils, and other wastes to increase the volume of Finished Products. While the chemical content of Coal and other feedstock determines output, a Sample CTL Plant can convert 100,000 tons of 6,500 BTU/lb. average commercial/waste Coal and other wastes to 27.2 million gallons of Zero-Sulfur Renewable Diesel fuel

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.